|

|

Build Your Online Product Catalogs?

| Product Name: |

Flue Gas Desulphurization (FGD)

|

| Supply Ability: |

more than 5 sets |

| Related proudcts |

bag filter, desulphurization, |

| Specifications |

Used for sintering&power plant etc. |

| Price Term: |

FOB |

| Port of loading: |

Shanghai Port |

| Minimum Order |

1 |

| Unit Price: |

by negotiation |

|

By researching on abroad and domestic desulphurization processes, the desulphurization methods can be generally divided into 3 categories as: pre-combustion desulphurization, in-combustion desulphurization and after-combustion desulphurization, wherein the after-combustion desulphurization is also known as FGD (Flue gas desulphurization). The FGD technology can be divided into the following five categories according to the desulphurization agent type: CaCO3-based (limestone) type, MgO-based type, Na2SO3-based type, NH3-based type and organic alkali-based type. The CaCO3-based (limestone) type is commonly applied in the present world and the proportion is more than 90%. As per the absorbent and desulphurization byproducts state (wet or dry) in the desulphurization process, the desulphurization technology can also be divided into wet method, dry method and semi-dry (wet) method.

This process is the world's most widely used technology, which is applied in the coal-fired power plants of more than 90% in Japan, Germany and the United States.

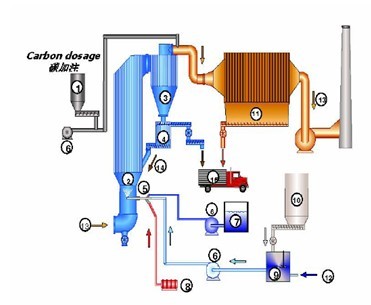

Its working principle is: the limestone powder is made into slurry by adding water, which is pumped into the absorbing tower for fully mixing with flue gas. The sulfur dioxide in flue gas and the calcium carbonate in the slurry will react with the help of air pumped from under, during which period the calcium sulfate will be produced. When the calcium sulfate reaches certain saturation, it becomes dihydrate gypsum. The gypsum slurry discharged from the absorbing tower will be concentrated and dehydrated, and then its water content will be less than 10%. Conveyor will send the dry gypsum to storage for stacking. After desulphurization, the flue gas will be discharged into the atmosphere by chimney by passing through the mist eliminator and heat exchanger. The absorbent slurry in the absorbing tower will be circulated by pump, so it can contact with the flue gas repeatedly, accordingly its utilization rate is high and the calcium-sulfur ratio is low. Generally, the desulphurizati |

| Company: |

VCEE Engineering & Technology Co.,Ltd

|

| Contact: |

Ma xu |

| Address: |

3188#, renmin road, pingjiang District |

| Postcode: |

215000 |

| Tel: |

8615995463747 |

| Fax: |

8651262629118 |

| E-mail: |

|

|

|

|